As a writer specializing in academic analysis and commentary, I would like to explore the various application scenarios of cnc drilling machines. These machines have revolutionized the manufacturing industry by providing precise and efficient drilling capabilities.

The Versatility of CNC Drilling Machines

CNC drilling machines are widely used in industries such as aerospace, automotive, electronics, and construction. Their ability to automate the drilling process with high precision makes them indispensable for mass production and complex projects.

In the aerospace industry, CNC drilling machines play a crucial role in manufacturing aircraft components. They can drill holes on different materials such as aluminum alloys or composites with consistent accuracy. This ensures that critical parts fit together perfectly during assembly.

Similarly, in the automotive industry, these machines are utilized for producing engine blocks, transmission cases, and other vital components. The automated nature of CNC drilling machines allows manufacturers to achieve faster production rates while maintaining quality standards.

The Advancements by Conprofe Ultrasonic

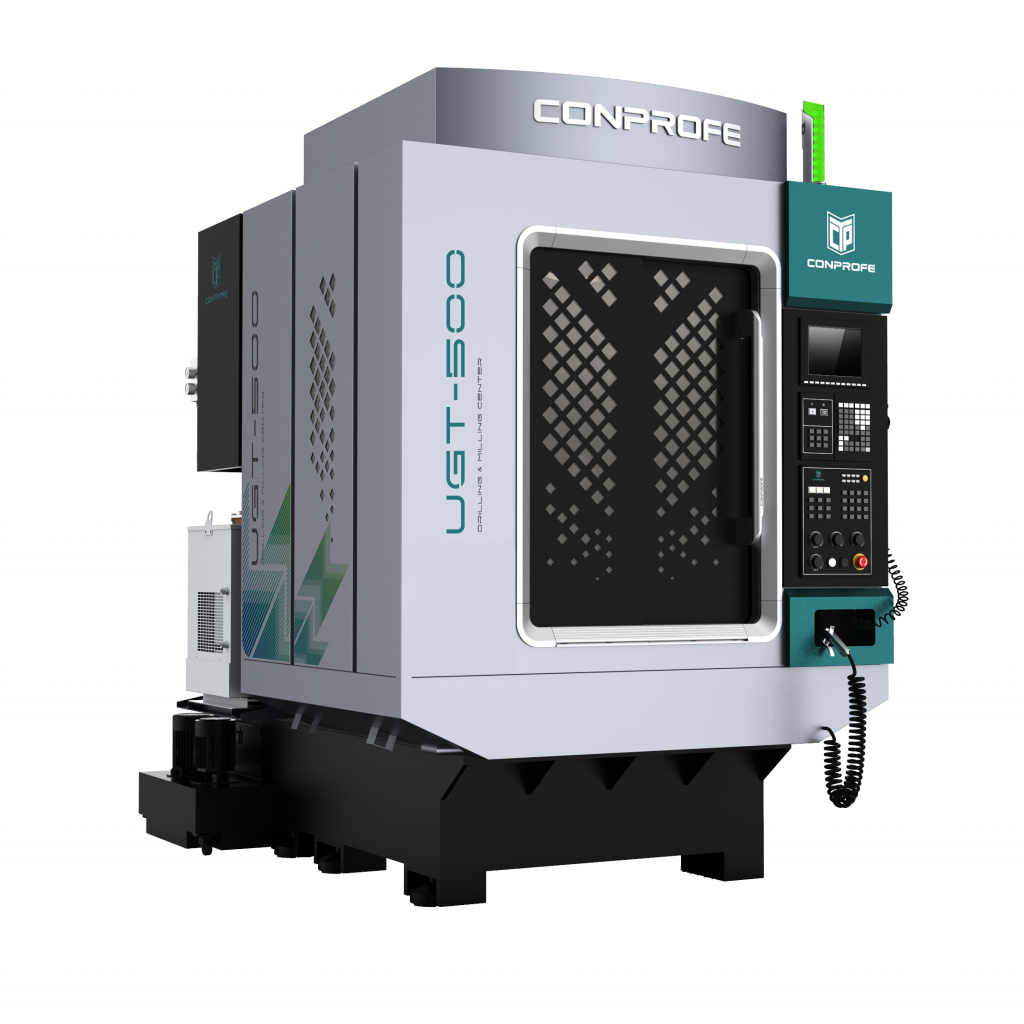

Conprofe Ultrasonic is one company that has made significant advancements in CNC drilling technology. Their ultrasonic-assisted machining technique enhances the performance of these machines even further.

By introducing ultrasonic vibrations during the drilling process, Conprofe Ultrasonic’s technology reduces friction between the drill bit and workpiece material. This results in improved chip evacuation and reduced tool wear. As a result, productivity increases while maintaining superior hole quality.

Gantry Machining Center: A Game Changer

gantry machining centers equipped with CNC drills have become increasingly popular due to their versatility and large working area capacity. These centers offer multi-axis movement capabilities along with advanced control systems that allow for complex operations.

This type of machine is particularly useful in the production of large-scale components, such as those used in shipbuilding or wind turbine manufacturing. The gantry structure provides stability and precision during drilling operations on oversized workpieces.

Furthermore, the integration of CNC technology allows for efficient programming and customization options. This flexibility enables manufacturers to adapt their processes according to specific project requirements.

Conclusion

-1-1024x1024.png)

CNC drilling machines have transformed various industries by providing precise and automated drilling capabilities. Their versatility makes them indispensable in aerospace, automotive, electronics, construction, and other sectors. Companies like Conprofe Ultrasonic have further enhanced these machines’ performance through innovative technologies such as ultrasonic-assisted machining. Additionally, gantry machining centers offer a game-changing solution for large-scale component production. As technology continues to advance, we can expect even more diverse applications for CNC drilling machines in the future.